Constructing Greens at Cutten Fields

- Feb 11, 2021

- 2 min read

During this past fall, many of us witnessed the completion of the new 15th green and bunkers, and the start of construction on the 13th and 16th holes. As this process has been halted by the winter season, Bill Green (Golf Course & Grounds Superintendent) and Jeff Mingay (Architect) have been busy working on preparing for the next phases for our Cutten Fields course improvement project. This includes planning, budgeting and preparing the technical specifications required for the construction of greens, bunkers, tees, drainage, irrigation, finishing and grassing. These specifications form the basis of the tender documents that will be sent out to qualified contractors that specialize in golf. We expect to complete the tender process and have a contractor in place by early spring in order to start the greens rebuilding in September 2020.

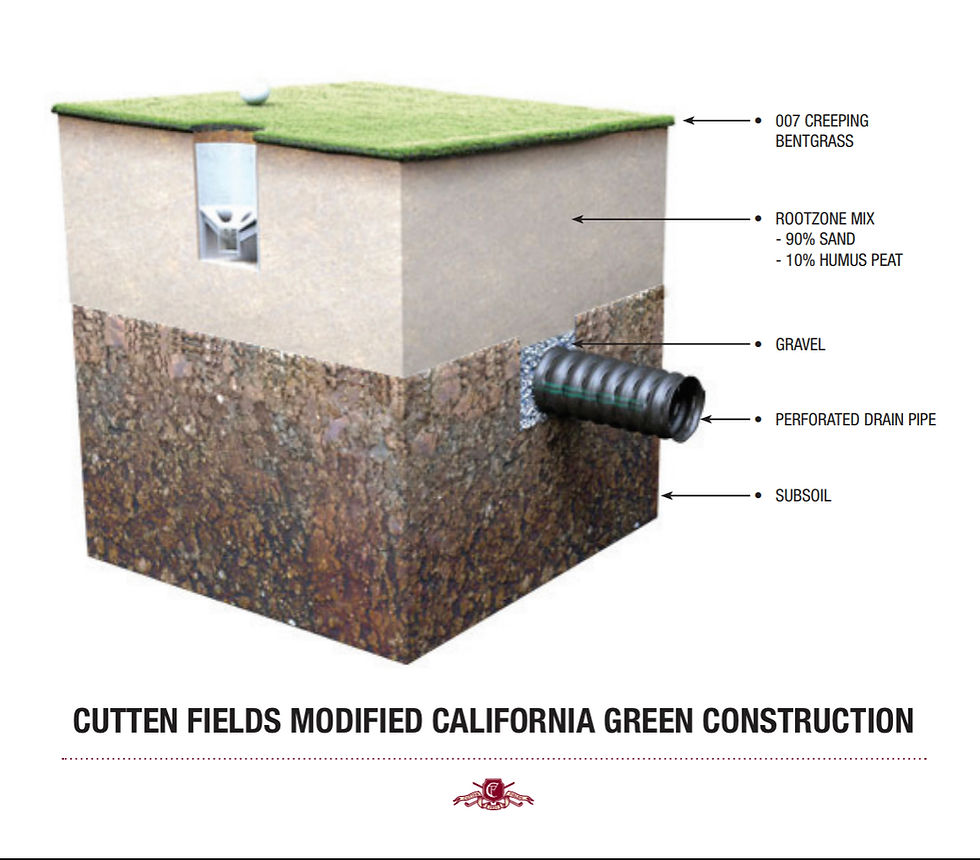

Building greens is a very precise and involved process. Modern greens are engineered to optimize root growth and plant health by maximizing soil physics, soil chemistry and sound design principals. Older construction methods, similar to the methods used to construct our existing greens that were built 1930, were constructed by pushing soil up to create the greens. In many cases, greens built in this era were designed to hold water as a means to maintain healthy turf with limited to no irrigation resources. The new greens at Cutten Fields will be constructed using a modified California green construction method, the same method used in construction

As we all witnessed last season with the birth of the new 15th green, here is some detail outlining the processes involved with building new greens at Cutten Fields.

A solid base is created with sub soil and it is at this point the architect will establish the slopes of the green;

Drainage systems are installed and will often exit at the low points of the green. Multiple exit points are ideal but not always feasible;

As part of the drainage system, view ports, slide valves and flush outs are installed. These allow staff the ability to monitor, flush and blow air through the system underground, if and when necessary;

The rootzone is comprised of 90% Sand 10% Humus Peat. The sand ensures good drainage and minimizes compaction while the peat will help with nutrient and water holding capabilities;

When selecting the rootzone mix for Cutten Fields, the sand underwent a series of physical tests to ensure the sand and peat meet the specifications outlined by USGA Guidelines;

Nutritional values and Ph of the sand were also analyzed and soil amendments were added accordingly;

Quality control measures are in place to ensure the consistency and quality of the materials are maintained throughout the building process as well as the quality of their installation;

Once grading and finishing is complete, the surface will be ready for seed. Seeding and bentgrass will be a future article of Rediscovering Cutten Fields.....Grow with Us.

Comments